Updated in March 2023.

You’re ready to start growing your ecommerce business. You’ve found a potential 3PL that matches your needs. But you may be wondering, how much does a 3PL cost ?

3PL costs vary depending on each company and the amount of service you need. You need to calculate 3PL cost based on various different factors, including your product size to shipping fees. Most 3PLs charge on four different areas, pick-packing, shipping, storage and integration. 3PLs also run on a volume discount basis, which means the more you send out, the cheaper these costs will become.

Let’s start by breaking down what is included.

1. Receiving Costs

Before actually processing and fulfilling an order from your ecommerce platform, 3PLs need to receive your inventory first. Hence, ‘receiving’ refers to the acceptance of the delivery of your products.

Receiving costs also cover the verification process and warehousing of your inventory. The labour of uploading the product information on the 3PL’s management system could also be charged. This cost can vary and be based on per hour, by unit, by carton, by pallet, and so on.

The factors within the receiving cost may also differ depending on the 3PL company, so it’s wise to check how the 3PL calculates it.

2. Storage Costs

When you store your inventory at a 3PL warehouse, 3PLs will charge you for storage space. It can be either long-term or short-term, with individual storage arrangements. 3PLs usually charge storage costs monthly and can be based on per-SKU, per-unit storage, per pallet, and so on.

Some other factors to consider are methods to store your products. For example, if you need to keep your product at a specific temperature, additional costs may incur.

Again, this depends on how the 3PL company has set its costs, so be sure to check.

3. Pick and Pack Costs

Picking and packing refer to the process that occurs once your customer places an order.

In picking, 3PL warehouse workers physically go through the warehouse to locate and pick the ordered items from their designated storage location. Costs usually depend on the number of picked items. It can incur for each pick or from a certain number of picks.

After picking, the items are packed for shipment according to the delivery instructions placed within the orders. Parcel requirements can be a factor in the packing costs. For example, the bigger the packaging material or the size of the parcel, the more expensive it could be.

Another factor that could incur costs is personalisation services, where 3PLs fulfil orders with specific needs. Examples include adding personalised letters and combining parts to complete a product.

4. Shipping Costs

Shipping refers to the inbound and outbound of an item. Inbound is where your inventory reaches your 3PL partner’s warehouse. Outbound is where your inventory leaves the 3PL’s warehouse to head towards your customer.

It’s just like when you have to fulfil an order by yourself. You have to pay for shipping, even when outsourcing the fulfilment process. However, the shipping rate can be much lower through 3PL. This is possible because of the 3PL’s courier partnerships and their access to high-volume discounts.

Other factors that affect shipping costs are:

- product/parcel weight;

- how quickly you want to fulfil;

- how your product will be sent (by air, sea or land);

- custom needs (such as fragile, foods, etc.);

- destination area; and so on.

So, when you want to know how much 3PL costs, it’s nice to keep in mind that these are the four main factors they’re based on.

“Are there other cost factors?”

There are services that some 3PLs may charge you for, while some may not.

Let’s look at two main services that fit this description.

The first service is onboarding support. Generally, onboarding refers to connecting your online shopping site to the fulfilment centre’s management system. Onboarding can include other services, such as integrating API and creating an account on their management platform.

The second service is kitting. Kitting means creating a product set or kit by assembling individual products. In this case, the 3PL needs to combine multiple SKUs. This manual handling is where the additional cost can come from. This is sometimes called ‘additional picks’ or ‘assembly’.

There is more variety of factors that determine the cost of using a 3PL. Therefore, we highly recommend asking a 3PL directly for more information.

“How cheap is it compared to in-house fulfilment?”

To compare, you will need to get a quote from a 3PL and calculate your fulfilment cost per order (CPO).

3PLs usually either have a cost model on their website or provide quotes. To get a quote, you need to contact them and provide details on your fulfilment, such as monthly order volume and average order cost.

For starters, why not try and contact us at KeepSpace? We’re available by phone and email, and we would always love to meet in person to talk about helping to grow your ecommerce business.

Next, you need to calculate your CPO for easy comparison. CPO refers to the sum of all the logistics expenses involved in in-house fulfilment, such as:

- receiving and storing the product,

- fulfilling orders (picking, packing and shipping),

- returns processing from customers,

- warehouse loan, and so on.

You can calculate your CPO by dividing the total costs for a year by the number of orders within the same year. While it is not your actual running costs, it is enough to compare with your 3PL quote(s).

If you want to look into more details, you will need to get several other data to calculate. This will depend on how detailed you want to be.

Here is a brief list for you to start on a little more detailed calculation:

- Annual net sales ($) – the gross sale net of product returns and exchanges.

- Annual orders shipped – the number of orders that were fulfilled.

- Total order lines – the total lines ordered on the marketing orders.

- Direct/indirect labour ($) – other labour such as warehouse maintenance.

- Total occupancy ($) – also known as ‘fixed CPO’, generally referring to the facility costs.

- Entire packaging supplies ($) – the cost of any boxes, envelopes and dunnage used for packing.

There are several other ways to calculate CPO. If you want to dig in deeper, it will be good to check them out. Or, if you only want to know an average of how cheap 3PL costs are compared to in-housing, check out this page.

“Can 3PL costs change? If so, how will they change?”

Yes, 3PL costs can change. How it changes will depend on your business situation, as 3PLs adjust their services according to your needs.

Businesses always have their ups and downs, and that is the same for ecommerce businesses. For example, let’s say your product is a seasonal item, and it is currently off-season. It will sell less compared to when it is on-season. When that happens, you will likely lower your production rate in response.

Just like how you respond to your business’s situation, 3PLs can do that too. 3PLs adjust their service level according to your order volume. Continuing from the previous example, fewer sales means you don’t need much storage space for that season. 3PLs can scale down your allocated space, so you won’t have to pay extra for what you’re not using.

This applies to the opposite situation as well. During the on-season or the holiday shopping spree, 3PLs will automatically scale up their services to fulfil the increased order volumes. This will also happen if your ecommerce business is growing overall. In these cases, the cost will increase accordingly.

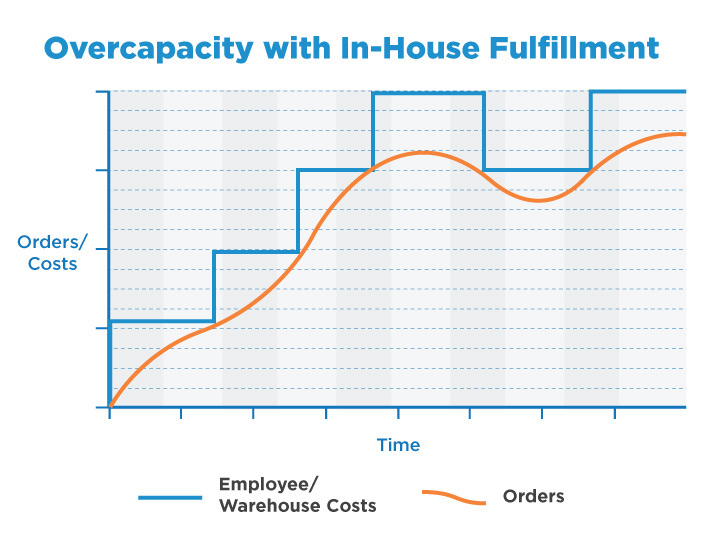

A similar process will occur even when you are doing in-house fulfilment. However, scaling your storage and labour is harder to accomplish by yourself. You won’t be able to adjust your storage loan according to your sales, and it’s a hassle to get the extra labour during holiday shopping. 3PLs can handle this in a much more flexible manner.

3PLs care about your business situation, so they will make sure that they provide the best solution for your case.

Summary: How much does a 3PL cost?

How much a 3PL costs vary from case to case. Therefore, it is highly recommended to communicate with your 3PL of interest for detailed breakdowns.

Factors that can influence the cost includes:

- Difference between 3PL companies;

- Receiving

- Storage

- Pick and Pack

- Shipping

- Your own business situation;

- Product metrics and requirements

- Order volume

- On/Off-season, and more.

Now you have an idea of what is included in a 3PL cost.

Your next step is to that quote to see if you should utilise a 3PL.